PROFILE

Pictures: Koninklijke Marine, IHC, M. Fluks

Motivation

As a young boy I was already fascinated by inventing, constructing and operating machines and equipment. This has remained over the years and I am still interested in the background and principles of existing systems.

First practical experience

My first experience with mechanical systems and associated drive solutions, after my education as mechanical engineer at Technical University Eindhoven, was gathered in the Royal Netherlands Navy.

Many aspects encountered when transferring loads between sailing ships, or when lifting floating objects out of the seawaves, are found back in later projects and applications.

Examples are: (vessel) motion compensation, control of forces, electrical and hydraulic drives, accurate control systems, and structural steel and machine construction.

Further career

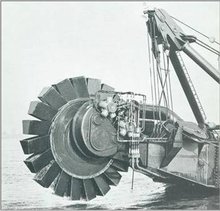

Later I worked in dredging, ship and crane building sectors; here integration of different technologies played an important role in the design process. During my engineering and technical development activities at IHC, STORK, Hydraudyne and Bosch Rexroth I worked on innovation and improvement of products, systems and contributed to renowned projects.

My focus was on mechanical systems and equipment with drive and control technology as essential element.

Many complete and fine functioning systems, ranging from simple to very complex, have been realized in a wide variety of sectors.

Examples are found in the Experience page.

Drive systems

The drive system technologies as used in different projects comprise:

• hydraulic

• mechanical

• electric

• hybrid

Each time a comparison and assessment is necessary to determine why one or the other solution would prevail in a particular case.

Work areas

Assignments are related to subjects on land or at sea, but often to the transition area between the two.

Conseon

Since 2010 my views, know-how and experience are available via Conseon.

Copyright © All Rights Reserved